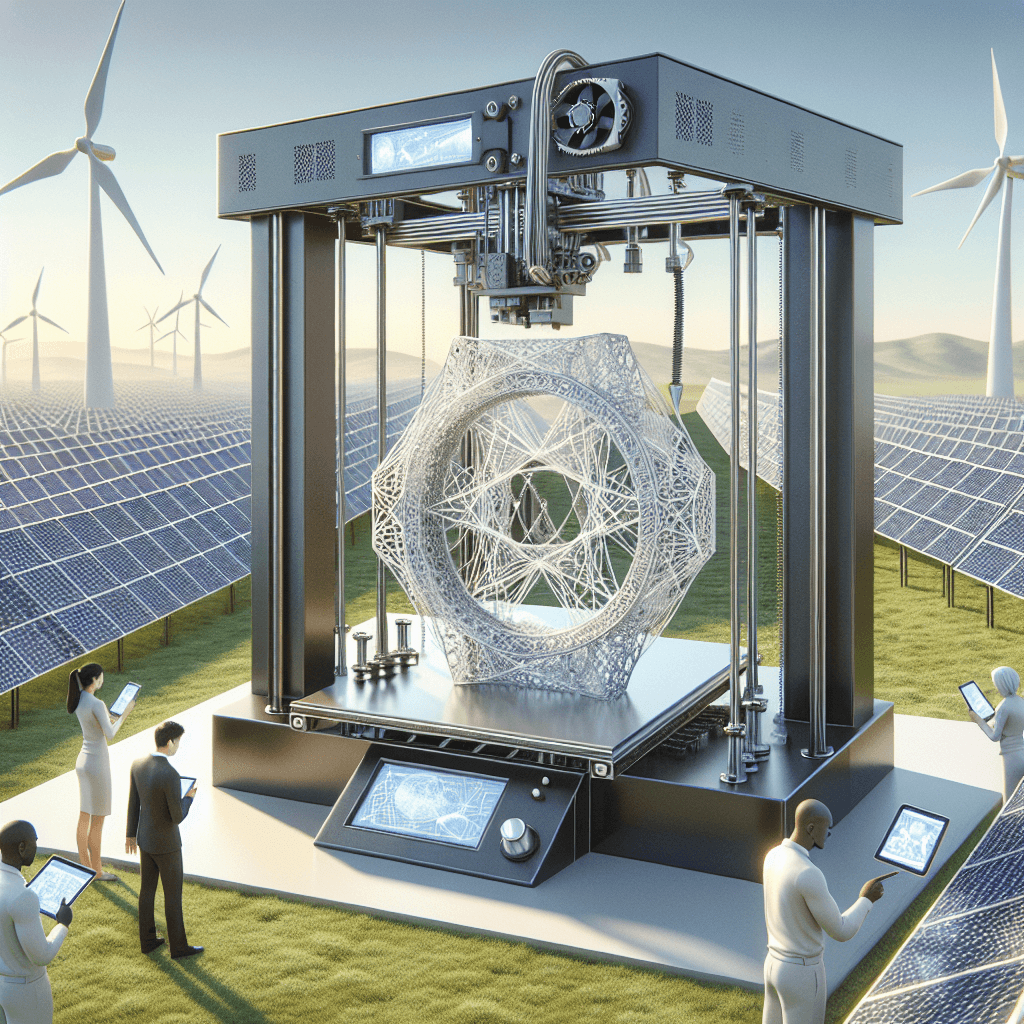

Can the rise of 3D printing technology herald a new era of sustainability? As the world grapples with the pressing need to transition to renewable energy systems, the unexpected hero could be a technology primarily known for creating plastic figurines and prototype parts. 3D printing, once a niche hobby for enthusiasts, is rapidly transforming into a pivotal force in the manufacturing world. This revolutionary method, also known as additive manufacturing, allows for intricate designs and swift production, characteristics that could potentially overcome barriers in renewable energy deployment, such as high costs and complex component fabrication.

Harnessing the power of renewable energy is more than a matter of environmental responsibility—it’s a design challenge requiring innovation and creativity. Enter 3D printing, a process that has shifted paradigms across numerous industries and now stands at the forefront of renewable energy technology. The advancements in additive manufacturing are redefining what’s possible, from the creation of intricate solar panel designs to the production of custom parts for wind turbines and batteries for energy storage.

Customizing Solar Solutions through Additive Manufacturing

Solar energy technology has advanced significantly over the past few decades, transitioning from simple, flat panels to more complex designs. 3D printing enables engineers to prototype and manufacture solar panels with unprecedented precision and customization. The key here is to focus on photovoltaic cells’ efficiency, and additive manufacturing is playing a big part in optimizing these energy-collectors.

Within the varied terrain of solar technology, 3D printing has introduced a new realm of geometric freedom. Imagine solar panels that conform to the curves of a building or settling comfortably on irregular surfaces that would make traditional panels balk. The customization doesn’t end there—additive manufacturing processes allow for the adjustment of solar absorptive materials at the microscopic level, enhancing the panels’ performance in different environmental conditions.

Bringing such specificity to the table results in maximized energy capture. Lightweight structures are now a possibility as well, reducing transportation and installation costs. These factors join hands, lowering the barriers to entry for solar energy, making it more accessible, and, you guessed it, furthering its appeal.

Reinventing Wind Energy with Precision and Efficiency

Wind turbines might seem straightforward in their towering grace, but they are a product of intricate engineering and material science. Traditional manufacturing methods have imposed certain limitations on the components’ design and efficiency. Now, thanks to 3D printing, those limitations are dissipating like morning fog.

Additive manufacturing’s precision is pivotal when it comes to optimizing the aerodynamics of wind turbine blades. Aerodynamic efficiency translates directly into how much wind energy is converted into electricity. With 3D printing, each blade can be tailored to not only its specific location but even the prevailing wind conditions of that site.

But it’s not all about the blades. Even the internal components of wind turbines are getting a 3D printed makeover. Gearboxes, for instance, benefit from smoother surfaces and more precise geometries, reducing friction and wear. These improvements curtail maintenance needs and prolong the turbines’ operational lifespans, ultimately bringing down the cost per kilowatt-hour of the wind energy produced.

Energy Storage Devices: Powering Up with Customization

Innovation in energy storage is another area where 3D printing is making waves. The efficiency of renewable energy systems is closely tied to how well they can store the produced energy. This is where advances in battery technology, partly fueled by 3D printing, come into play.

3D printed batteries are not some distant future concept; they are unfolding in the here and now. By building battery components layer by layer, additive manufacturing permits the construction of more sophisticated structures that improve conductivity and offer larger surface areas within smaller volumes. This leads to batteries that charge faster, hold more energy, and retain charge longer, which is crucial for both grid and off-grid applications.

Moreover, the speed of prototyping offered by 3D printing allows for rapid testing and iteration, accelerating the development of new battery chemistries and configurations. This agility is indispensable in a field that moves as quickly as renewable energy storage and is constantly hungry for improvements to integrate seamlessly with various renewable sources.

Accelerating Innovation and Sustainability

The ripple effects of introducing 3D printing into the renewable energy sector are palpable. Take sustainability, for example. Traditional manufacturing methods often involve subtractive processes—start with a block of material and carve out what you don’t need, leaving behind excess waste. With 3D printing, the approach is additive—you use only the material necessary to create the component, significantly reducing waste, and promoting sustainability throughout the production cycle.

The reduction in material waste couples with the lower energy requirements of 3D printing processes to further bolster the environmental credentials of renewable energy components. When the means of production align with the ethos of the end product, it’s a win-win for those invested in a sustainable future.

Furthermore, the localized production capability that 3d printing facilitates is a game-changer. Instead of relying on large, central manufacturing plants and dealing with the logistics of shipping parts across the globe, renewable energy components can be printed closer to where they will be installed. This decentralization of production mitigates transportation emissions and sharpens the edge renewable energy has over traditional fossil fuels in terms of carbon footprint.

It is apparent that 3D printing is much more than a technological fad. In the realm of renewable energy, it is a mover and shaker, playing a critical role in shaping a future where clean energy is readily available, cost-effective, and produced with minimal impact on our planet.

The transformative influence of 3D printing across renewable energy applications promises more than just innovative solutions. It paves the path for a fundamental shift in how we conceive, produce, and use energy. In doing so, it embodies the synergy of human creativity and technological progress, pointing us toward a greener, more efficient future.